Sustainble Waste Systems

Cortex ™Superhuman sorting

speed and precision

AI-powered robotic sorting system

Sustainble Waste Systems

Cortex ™Sort twice as fast, with unmatched precision

Sustainble Waste Systems Cortex ™ is a high-speed robotic sorting system guided by Smart Waste Systemsgroundbreaking artificial intelligence (AI) technology. Our robots intelligently perform physical tasks of sorting, picking, and placing material to achieve up to 99% accuracy and up to 80 picks per minute.

benefitsLabor

Reduce time and money spent on high-turnover positions

Safety

Increase facility safety and reduce training overhead

Material Recovery

Capture more high-value material and boost your bottom line

Contamination

Decrease bale contamination and improve quality

The Power Behind Sustainble Waste Systems

Cortex ™The largest real-world data set of recyclable materials

70+

billion

items seen annually

300+

AI systems deployed globally

50+

identifiable categories

Sustainble Waste Systems SERVICE & SUPPORTOur Customer Support

At Sustainble Waste Systems, we’re driven by customer experience, and we carry out our work with customers at the center of everything we do. Our support program helps you maximize the return on your technology investment by giving you access to our best-in-class service team. The Sustainble Waste Systems SERVICE team is dedicated to elevating the operating success of your facility by ensuring each Sustainble Waste Systems Waste Systems Waste Systems Waste Systems product is meeting your expectations and running at top performance.

Customer success defines Sustainble Waste Systems success.

Recycling and Disposal Solutions (RDS) of Virginia

RDS of Virginia uses Sustainble Waste Systems Cortex ™ intelligent robotics systems to sort PET, HDPE, plastic film, cups, and metals at one of its Roanoke facilities.

Smart Waste Systems PRODUCTS

Explore more products from Smart Waste Systems

-

ARTIFICIAL INTELLIGENCE

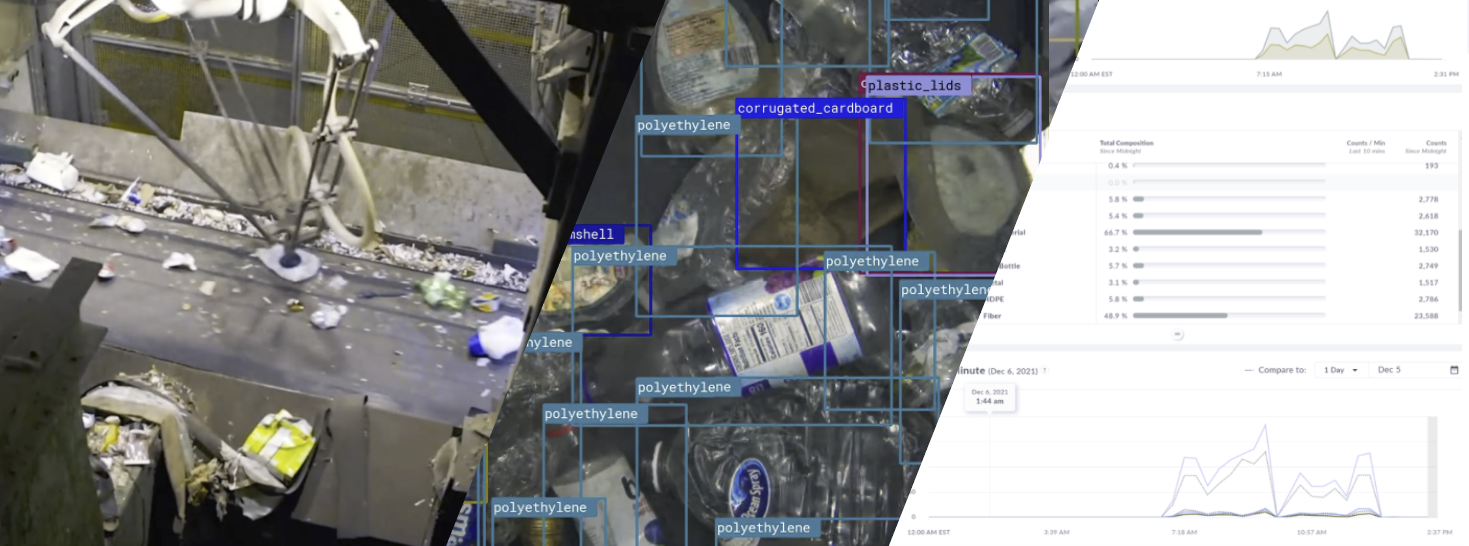

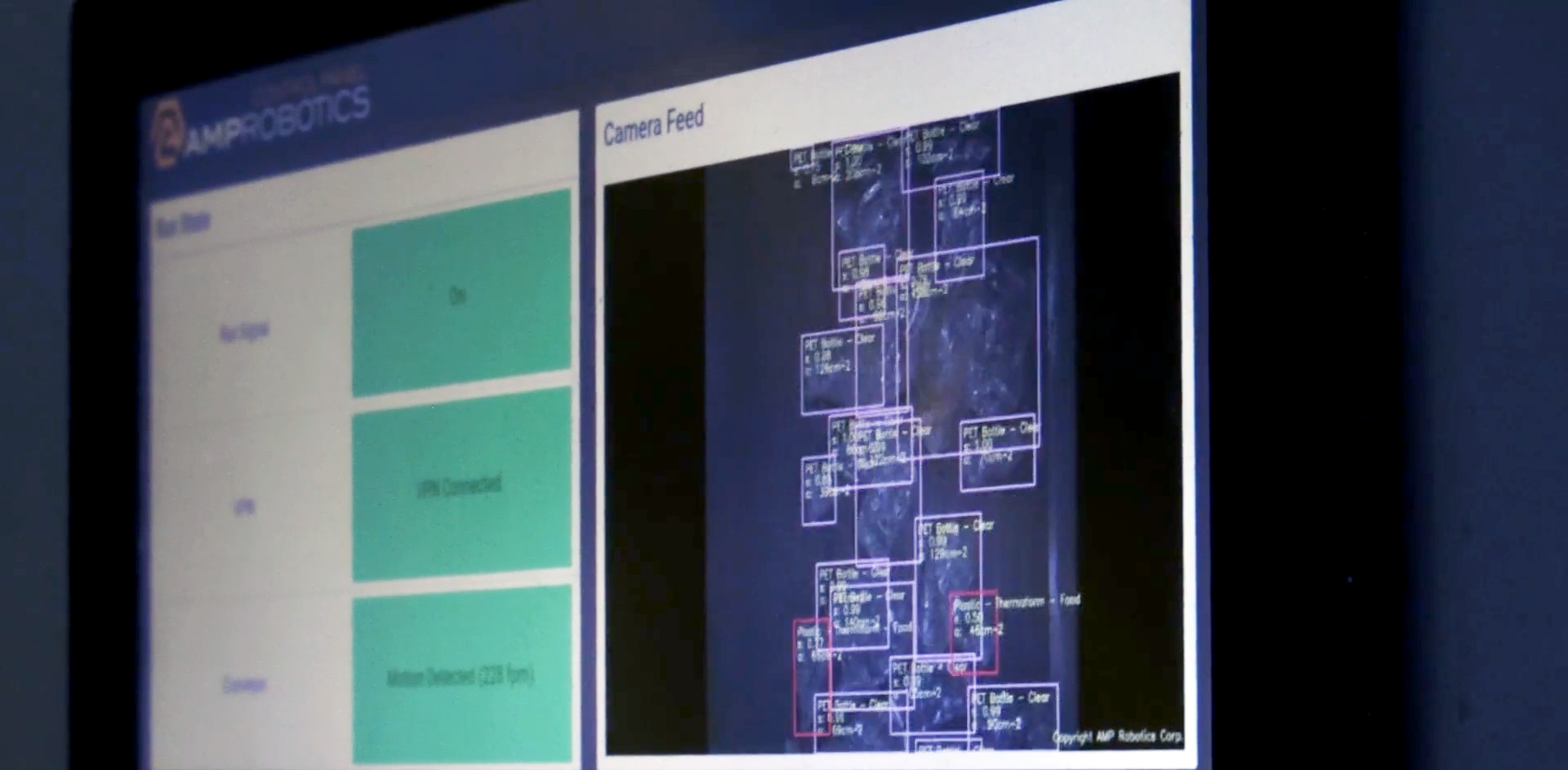

AI platform using computer vision to recognize patterns of specific recyclable materials within a complex waste stream of smashed, folded, and tattered objects—all combined together.

-

![]()

VISION SYSTEM

Modular computer vision system that you can drop into key stages of your operation to understand your material flow from inbound processing to bale QC to the end-of-the-line.

-

![]()

MATERIAL CHARACTERIZATION

Web-based data portal that provides real-time material characterization and performance measurement throughout key process stages of your sorting operations.